SAFETY NOTES: Because there is a possibility of bags exploding from overfilling and because one of the ingredients in the bag is an acid, ALL TEST RUNS OF AIRBAG DESIGNS ARE TO BE CONDUCTED IN THE HOOD WITH THE DOORS CLOSED AS COMPLETELY AS POSSIBLE.

GENERAL INSTRUCTIONS: Each Student should work as an individual for this lab.

Part I: Calculating the Volume of the "Airbag" |

|

|

Obtain 1 plastic empty “airbag” from the front counter and determine its volume. |

|

Fill your airbag as full as possible with water and use a graduated cylinder to calculate the volume of gas needed by determining the volume of water that filled the bag. |

Part II: Testing Your "Airbag" |

|

|

Use paper towels or Kimwipes to completely dry the inside of the bag. |

|

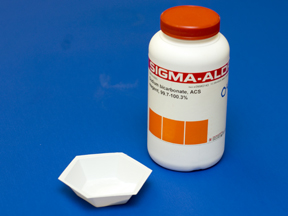

Weigh out your calculated amount of sodium bicarbonate and add it to your “airbag”. Be sure to record the exact gram amount you add. |

|

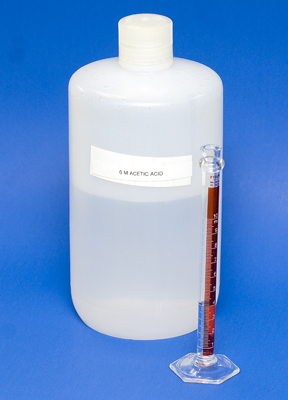

Measure out your calculated volume of 6.0 M acetic acid using a graduated cylinder. Record the volume to the nearest 0.1 mL. NOTE: Be very careful when handling the acid and wash your hands immediately if you get some on your skin. Acetic acid is not a strong acid but it will still cause irritation if left in contact with your skin. |

|

Take your graduated cylinder and “airbag” to the hood. Once at the hood you can test your airbag. Quickly but carefully pour your acetic acid into the “airbag” and seal it. Mix the ingredients completely by shaking and squishing the bag. |

|

Once the reaction is complete, be sure to make observations of the fullness of the airbag and whether or not the reagents seem to be completely used up |

|

Repeat steps 1 thru 6 making adjustments to your calculated amounts of reagents as necessary. Dump the remaining fluid in the bag in the waste jar in the hood and rinse and dry your bag thoroughly. Be sure to show a successful “airbag” to your TA before leaving. |